CNC Turning

Professional metal processing

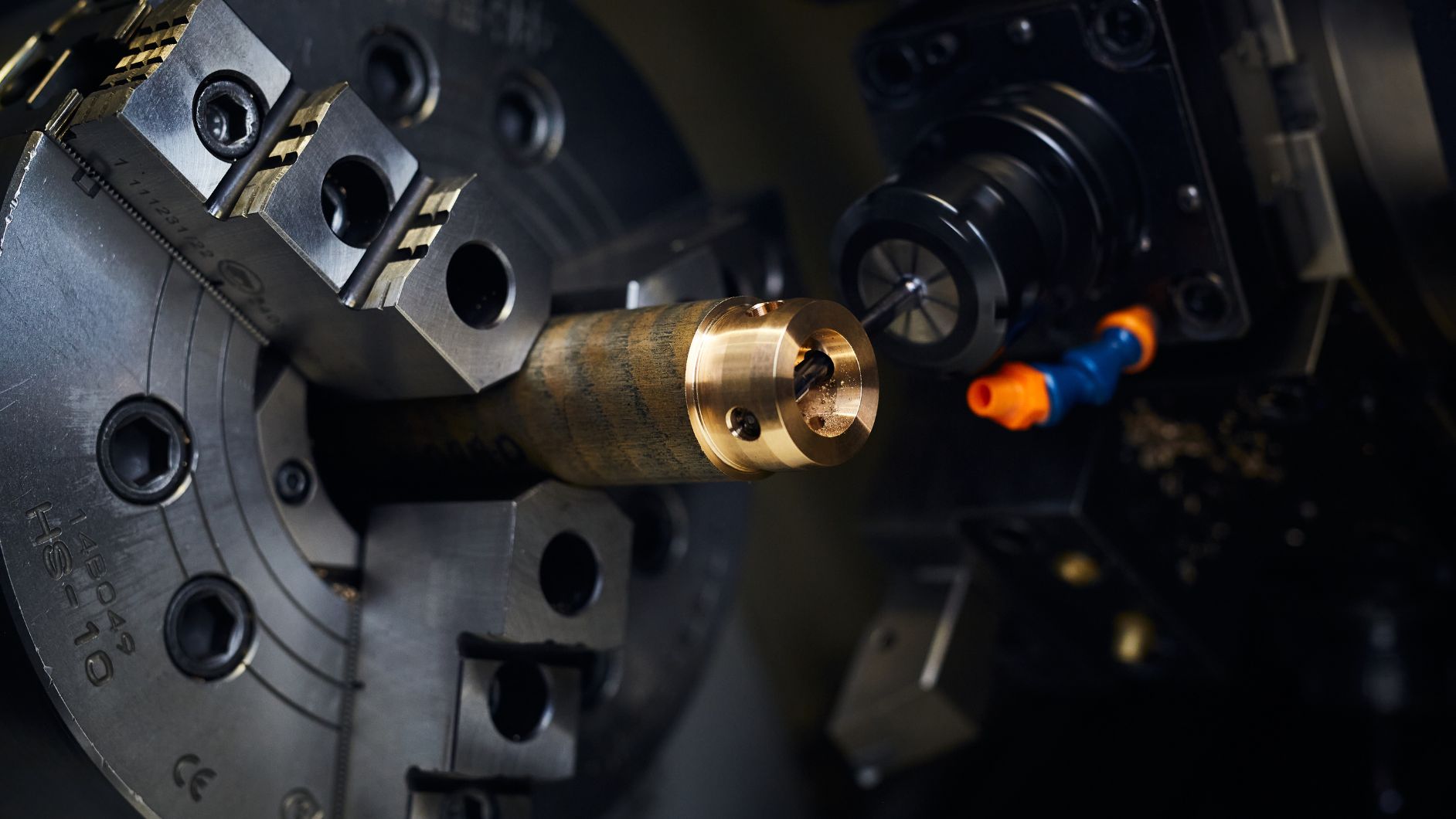

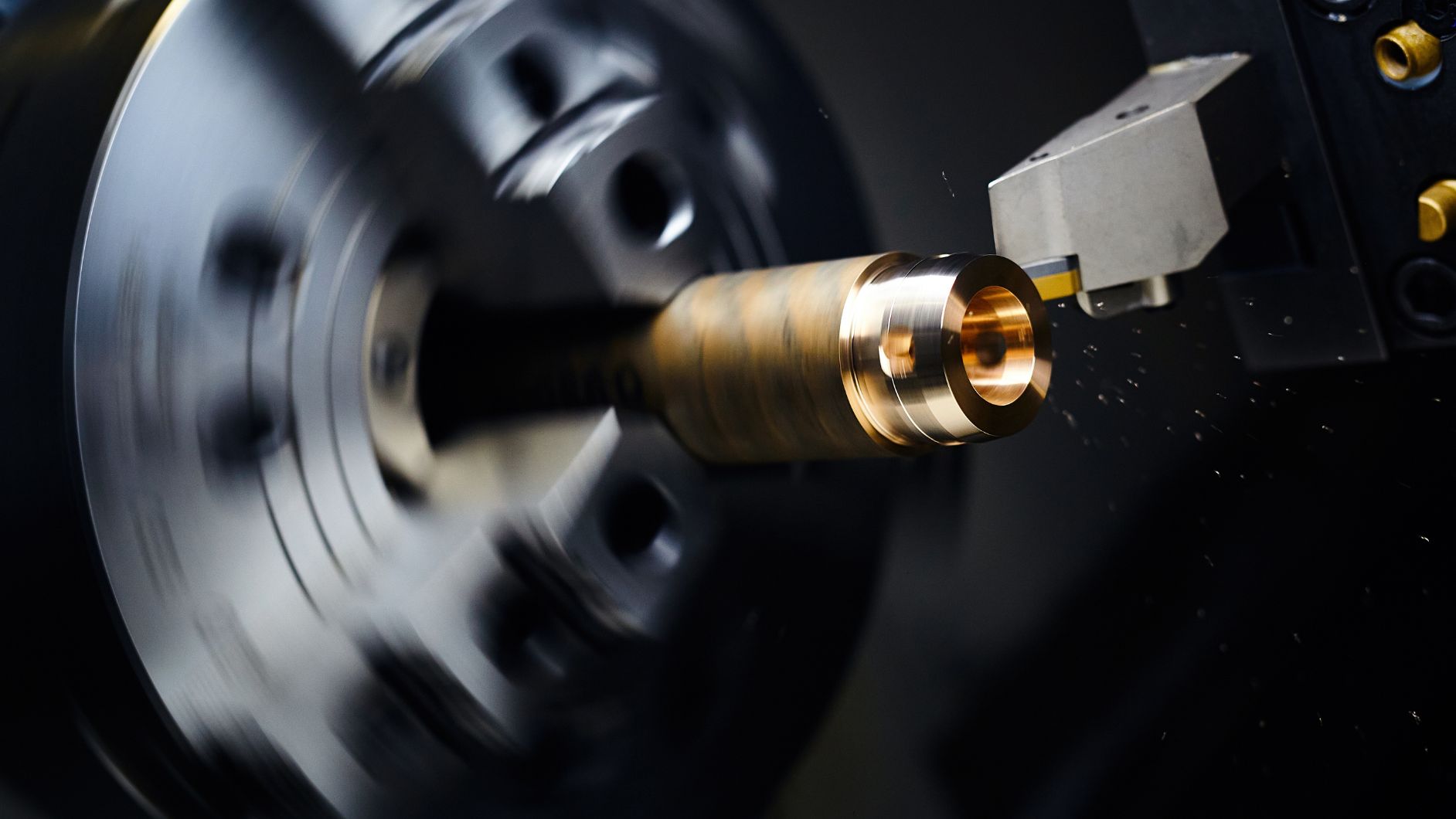

CNC Turning is a computer-controlled (CNC) numerical machining process that is used to produce precise and complex components or components for various industries. This precision manufacturing service is widely used in the automotive, aerospace, medical and engineering industries to produce components for turbines, engines and other machines.

The CNC process used in CNC Turning involves the use of specialised computer software to control and manipulate automatic cutting tools to shape and form materials, such as metal, plastic and wood, into specific shapes and sizes. This ensures consistency in production and reduces waste and errors, making it an efficient and cost-effective method of production.

The advantages of CNC Turning include a high level of accuracy, fast production, and flexibility in creating complex shapes and patterns. With CNC Turning, you can order parts tailored to your exact requirements, ensuring precise fit and functionality for individual components.

BUDRAD

CNC TURNING

CNC Turning

CNC Turning is a machining technology that offers exceptional accuracy and speed, making it ideal for companies that require large-scale production. The process uses computer-controlled machines to cut and shape materials to exact specifications, resulting in perfectly formed components that meet or exceed industry standards. This technology has significant advantages over manual processing, including greater precision, faster execution times, and greater efficiency of material use. CNC Turning can be used for a wide range of materials – from metals to plastics – and can produce complex shapes with ease. It is an excellent technology for the production of complex parts for various industries, including aerospace, automotive and medical equipment. With CNC Turning, manufacturers can improve production efficiency, reduce waste, and provide customers with high-quality components that meet their unique requirements.

Comprehensiveness

We offer comprehensive CNC services. We have many years of experience in CNC machining (turning, milling); we have our own design department and a staff of well-trained employees. We make ready-made details from metal and plastics. We carry out processes in accordance with the implemented ISO 9001:2015 Quality Management System.

Reliability

Thanks to the care and attention paid to each order, we acquire a group of satisfied customers year by year. We are constantly developing our machinery, training our team, and expanding our production capabilities. We work for over 130 small and large, local and global customers from the railway, machinery, automotive, household appliances, food and agricultural industries.

On time

We approach each order with the utmost care. We attach great importance to maintaining flexibility in customer service. We ensure the speed of order execution while maintaining the quality at the agreed level. Our priority is the punctuality of services provided while maintaining the highest quality and customer satisfaction.

CNC Turning

How we work at BUDRAD

From the beginning of our activity, we have specialised in the provision of machining services, using Computer-aided design (CAD) and Computer-aided manufacturing (CAM) technologies. Turning is carried out on CNC machines. We complete orders based on patterns, 3D or 2D documentation. We also assist in designing parts, assemblies or entire machines, based on the client’s concept. We design using SolidWorks software, which allows for 3D visualisation before machining. CAD/CAM technology shortens the time and costs of designing and prototyping, while maintaining high accuracy and repeatability of details. Machining (milling, turning) is our specialty.

We optimise manufacturing processes by selecting highly efficient machines, tools, processing parameters, process control techniques and finished product inspection, which allows us to achieve the lowest possible manufacturing costs, while maintaining the quality of the finished products agreed with the customer.

Turning (as an element of machining) can be carried out in combination with milling and/or other processes mentioned in the offer.

We work for over 100 small and large, local and global customers from the railway, machinery, automotive, household appliances, food, etc. industries.

We carry out processes in accordance with the implemented ISO 9001;2015 Quality Management System.

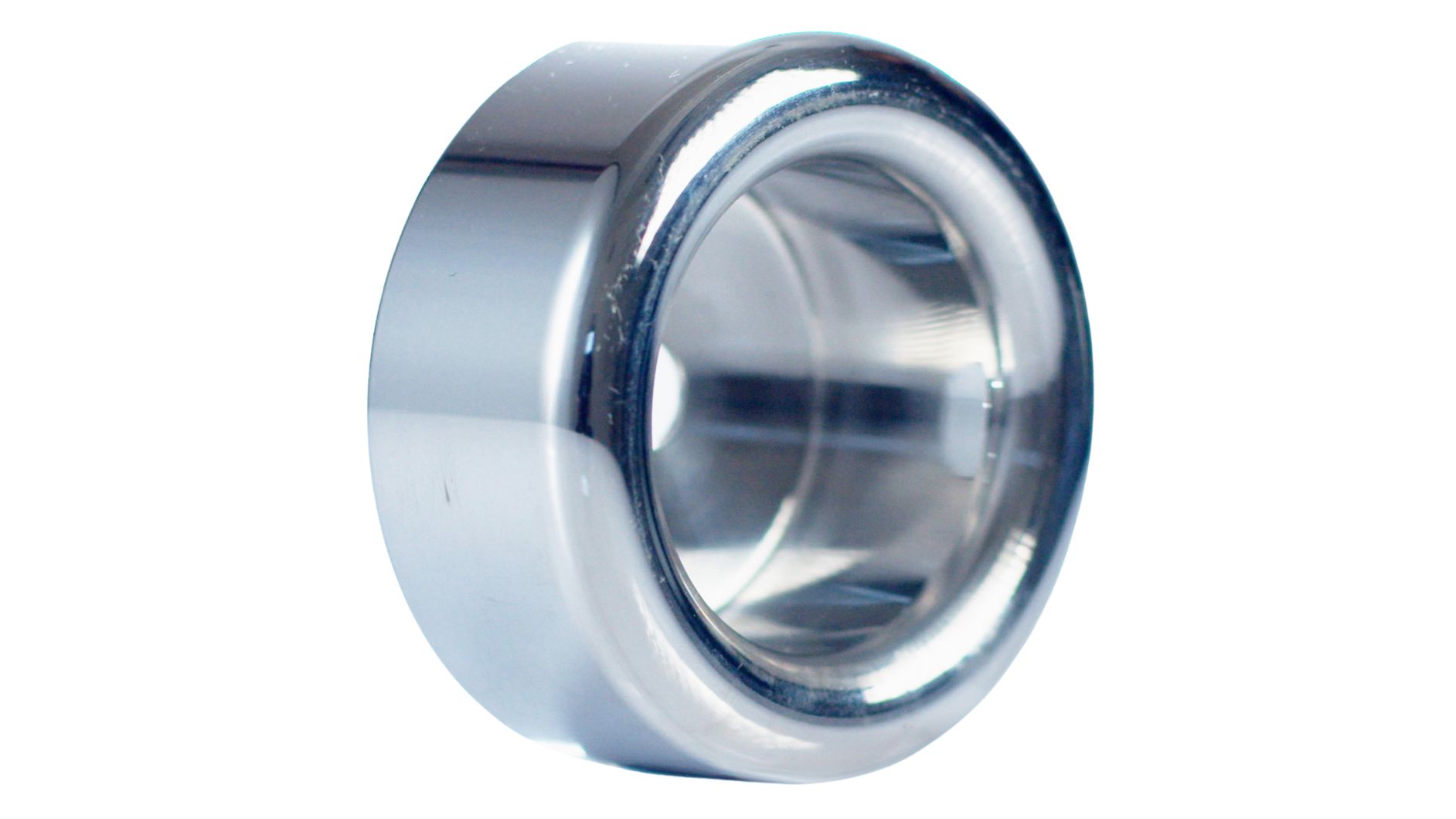

Standard manufacturing accuracy in accordance with ISO 2768-1-m. Greater precision, up to 5 μm, can be confirmed after detailed analysis of the detail.

We carry out medium and small production series, as well as individual orders.

Maximum dimensions of details:

- length 760 mm

- diameter 460 mm

- Steel (acid-resistant, stainless, tool, bearing, structural).

- Non-ferrous metals (aluminium, bronze, brass).

- Plastics (polyamide PA6, polyacetal POM-C).

We use a wide database of proven suppliers. We also produce using materials provided by the client.

Address:

BUDRAD POLSKA Sp. z o.o.

Rzędziany 50/1

Tykocin k.Białegostoku

Contact:

Tel: +48 85 674 77 26

Tel: +48 660 002 999

E-mail:

E-mail: biuro@budrad.com.pl

Office open: 7.00-16.00

Check out our offer

of CNC services

We are able to produce parts, structural elements, or design and build entire machines. Tell us what you need and we will design it, make it and deliver it to you within the specified time. Take advantage of our offer!